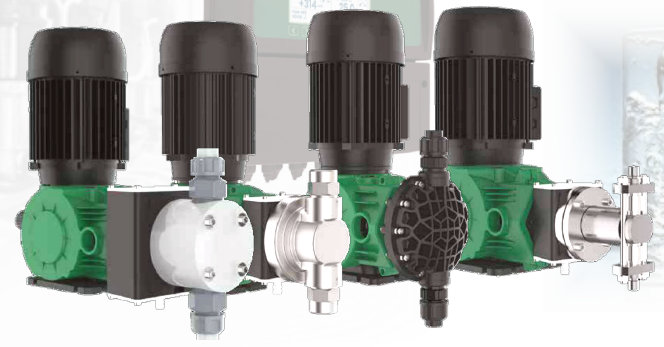

R2-R Model Pumps

Key Features

• Variable eccentric system exploits

motors power during suction and discharge phases for smooth linear output

• Exceptional

precision regardless of environment conditions optimising chemical efficiency and process control

• Higher torque specification motors increased piston sizes with spring-return mechanism for

low gearbox stress

• Multiple configurations of premium chemical resistant pump heads and seals

for the most aggressive chemicals

• Pumps equipped with either three-phase or single-phase motors

- Both with IP55 rated protection

• Comprehensive Flow Rate Outputs :- 400 litres/Hr to 1000

litres/Hr - Pressures up to 20 Bar

• Wetted parts: | SS316L | PVC | PP | PVDF| PTFE | FPM | EPDM | Ceramic |

R1-R Model Pumps

Key Features

• Variable eccentric system exploits

motors power during suction and discharge phases for smooth linear output

• Exceptional

precision regardless of environment conditions optimising chemical efficiency and process control

• Higher torque specification motors increased piston sizes with spring-return mechanism for

low gearbox stress

• Multiple configurations of premium chemical resistant pump heads and seals

for the most aggressive chemicals

• Pumps equipped with IP55 rated three-phase or single-phase motors

- Versions with 12 Vdc upon request

• Comprehensive Flow Rate Outputs :- 1.5 litres/Hr to 304 litres/Hr

- Pressures up to 20 Bar

• Wetted End Parts | SS316L | PVC | PP | PVDF | PTFE| FPM | EPDM | Ceramic |

Mechanical Piston-Plunger

Metering Pumps

Mechanical Piston Metering Pump

Piston metering pump range with spring return piston-plunger mechanism coupled with

unique fixed ratio gearbox that greatly reduces mechanical stress housed in robust epoxy painted aluminium casing

offering choice of multiple combinations of piston stroke lengths motor power and chemical resistant dosing heads, achieving multiple

hydraulic characteristics adaptable for a large number of applications where a lower flow rate metering pumps are best

suited to produce accuracy and performance regardless of working conditions.

Piston- Metering Pumps

Reliability & Performance

A motor-driven mechanical piston dosing pump is a heavy-duty

positive displacement pump that combines a fixed ratio gearbox driven by an electric motor moving the piston or plunger

inside the dosing head in a reciprocating action to draw and then discharge chemical into the process, know to

be highly efficient a pumping viscous liquids or heavy chemical with the pumps flow rate relatively unaffected by changes

in the systems backpressure with adjustment output respectively being linear throughout the dosage

scale. The robust design with multiple motor options allows them to be used in high pressure processes such

Mechanical Plunger Dosing Pump

Mechanical plunger dosing pump range housed in robust epoxy painted aluminium casing

designed to operate over long periods with fixed ratio gearbox coupled with spring return plunger-piston mechanism

increasing precision and performance whilst minimising mechanical stress due in principle to the high torque motors, the flow

rate can be adjusted either manually or automatically through a motorised actuator which operates off a current 4-20mA

input signal often from process instruments such as pH-Chlorine-Redox controllers. Multiple combinations of compatible

dosing heads resistant to most chemical agents maintaining consistent accuracy and performance even in demanding higher

flow water treatment applications.

Plunger Dosing Pump

Mechanical plunger dosing pump specifically designed to operate at 100 bar pressure with

equipped with special reinforced pump body with fixed ratio gearbox spring return piston mechanism coupled

with high torque motor to maximise consistent repeatable precision whilst minimising mechanical stress in

high pressure applications, pumps flow rate is adjustable manually or automatically through an actuator that

operates off a current 4-20mA input signal often from process instruments such as pH-Chlorine-Redox controllers. Multiple

combinations of compatible dosing heads resistant to most chemical agents maintaining consistent accuracy

and performance even in demanding higher flow water treatment applications.

R2-HP Model Pumps

Key Features

• Variable eccentric system exploits motors power during suction

and discharge phases for smooth linear output

• Exceptional precision regardless of environment conditions optimising chemical efficiency and

process control

• Higher torque specification motors increased piston sizes with spring-return

mechanism for low gearbox stress

• Multiple configurations of premium chemical resistant pump

heads and seals for the most aggressive chemicals

• Pumps equipped with either three-phase or single-phase

motors - Both with IP55 rated protection

• Comprehensive Flow Rate Outputs :- 2.5 litres/Hr

to 12 litres/Hr - Pressures up to 100 Bar

• Wetted Parts :- 316L Stainless Steel -

Premium Grade Seals :- PTFE - NBR

Electronic Dosing Systems

Tel 01299 825 656 Email info@electronicdosingsystems.co.uk

Solutions For All Metering & Measurement Processes

Copyright: - Electronic Dosing Systems 2026

| Water Treatment | Electroplating | Cooling Towers | Industrial Boilers | Beverage & Breweries | Vehicle

Washing | Waste Water Treatment | Swimming Pools & Spas |

| Paper Industry | Petroleum | Bottle Washing |

Hygiene & Cleaning | Biotechnology | Food Industry | Pharmaceutical Industry |

Precise Chemical Metering

A mechanical piston or plunger dosing pump flow rate is directly proportional to the stroke length

and motor speed due to their design the reciprocating action of the piston this linear relationship across the pumps dosage scale

retaining a flow tolerance & accuracy unaffected by chemical viscosity or pressure fluctuations.

Low Dependence on Back-Pressure

Mechanical

piston/plunger dosing pumps are fundamentally different to other types pumps the most significant advantage is that the pumps flow

rate output is independent on backpressure delivering a volumetric efficiency of between 90% to 98% displaced

per stroke whether the backpressure is 2 bar or 100 bar.

Flow Rates 9 ÷ 2300 l/Hr - Pressure 100 Bar